Service on

LNG and alternative fuel capable vessels

Nordan Marine provides services, repair and maintenance support to LNG and alternative fuel capable vessels. Our experienced service engineers are highly skilled in working with various brands.

To create great benefits for our customers in saving time and cost, Nordan Marine provides full package services for entire LNG and alternative Fuel Gas Supply System (FGSS) such as:

- Submerged and Fuel Pump Service

- Safety Relief Valves Service

- Calibration Services

- Service and Testing of high pressure safety valves

Our safety valve service, testing and certification service ensures compliance with regulations, reduces risks to safety, health, and the environment.

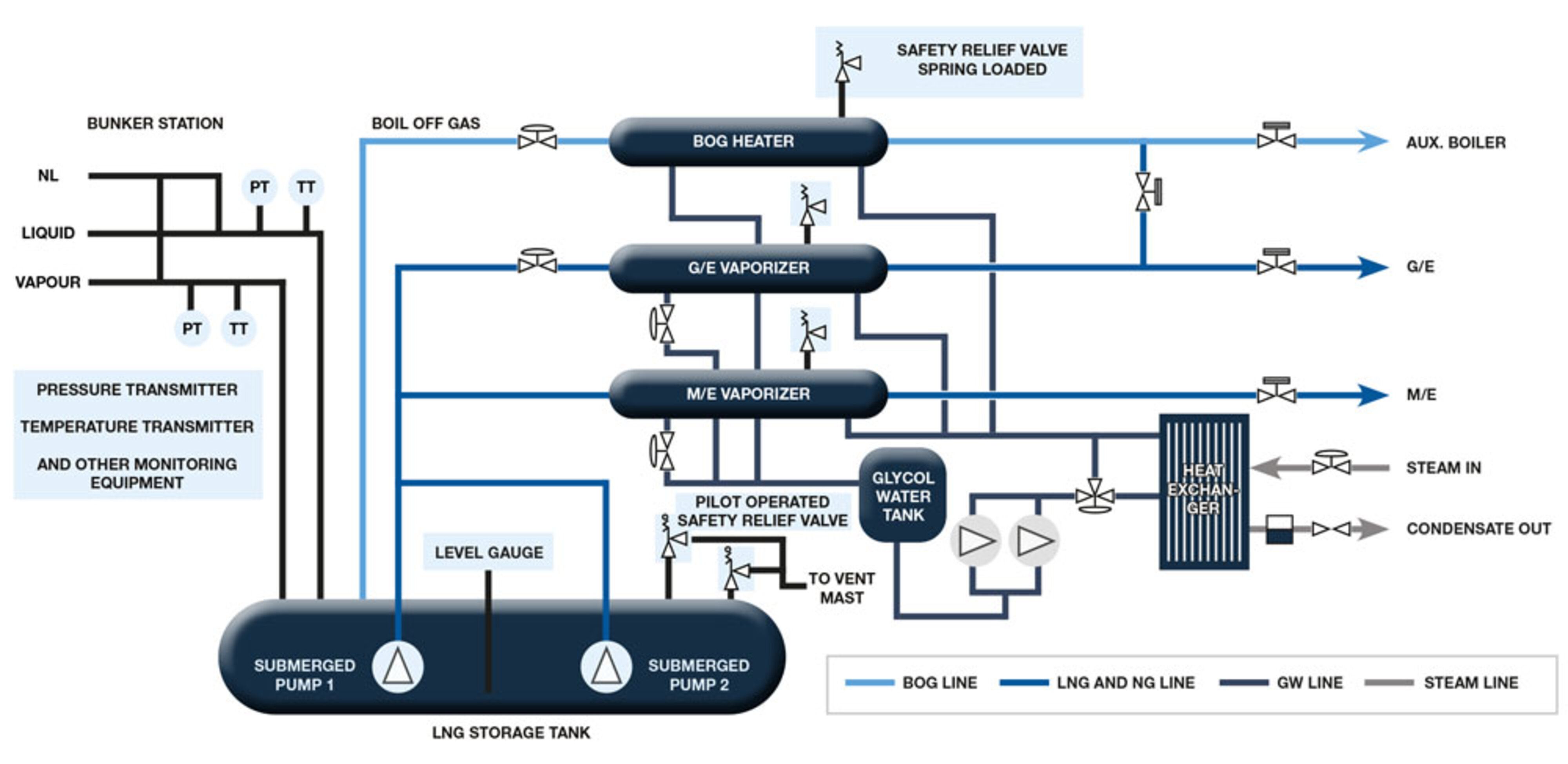

Schematic Process Diagram of FGSS Skid:

Our LNG Fuel service team offers you:

Calibration Service

Fully educated marine and service engineers with extensive mechanical and electrical experience.

Service and Testing of high pressure valves

- Safety Valves with set pressure above the standard N2 bottle of 180-200 barG

The high-pressure valves test service is carried out with Nordan Marine’s Power booster Unit (PBU). Our PBU is able to test high pressure valves up to 500 barG.

Advantages of using Nordan Marine’s PBU and tool kit to test high-pressure safety valves:

Save cost and avoid logistic issues:

- High pressure SRV testing can be performed on voyage in vessel’s workshop.

Minimizing downtime:

- Unforeseen breakdown can be addressed onboard using PBU and skilled service engineers.

Keeping your high performing SRV working in good working order:

- Planned maintenance can be performed onboard

- Certified equipment and personnel for onboard service

- Minimizing equipment failure and personal injury

24/ 7 Technical Support

You can always get contact with one of our technical support personnel from our head office when a cargo system is out of operation.

Our technical support personnel have extended experiences and knowledge in advising you to solve problem on-site, and then based on your situation and identified issues, we can provide you related analysis.

24-hour service: +45 9840 2440